It is a commonly held view that 70% of women are wearing incorrectly sized bras, although research carried out by Figleaves, the internet lingerie supplier, showed an even higher figure.

In addition, manufacturers size differently, so one brand’s 34DD might be another brand’s 34E. Bras from outside the UK often have completely different sizing schemes. In-store fitting is costly, can result in queuing and is embarrassing for some women.

Figleaves’ managing director, Daniel Nabarro, had an idea to enable a woman to quickly, easily and with no embarrassment, find the right size bra in the chosen style, which fits perfectly and enhances comfort and appearance. She would order from Figleaves a special tape measure (which works at constant tension so as to avoid the inaccuracies when using a normal tape measure), along with four specially-shaped volumetric cups and a set of instructions. In the privacy of her home, she would measure their underbust with the T-tape and the breast volume using the cups. She would then, via the Figleaves web site or the telephone order line, state her size – for example:

“I am a 48 band and a 5½ cup” and would be given a list of fitting bras: “Your best fit is: Playtex Essensis 32D, Wonderbra Gem 34C, Simone Perele 75D”.

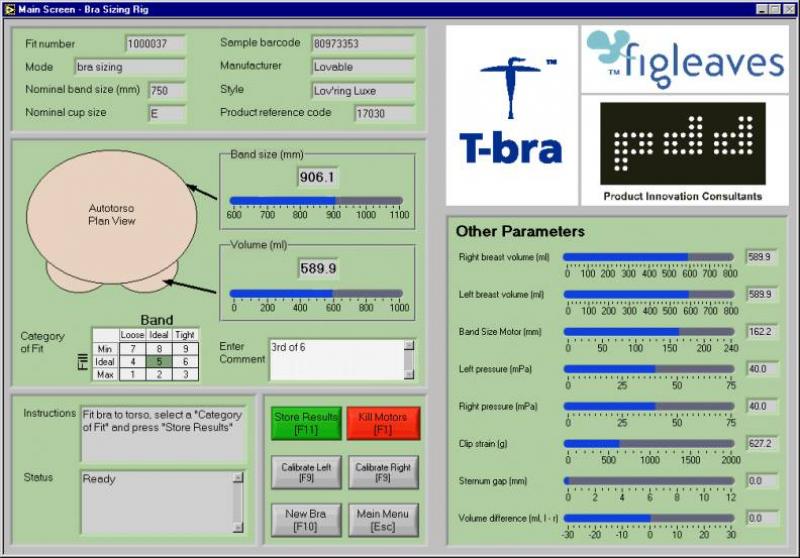

To make this idea a reality, a large amount of accurate sizing information would need to be gathered from thousands of bras – to give the mean size and the variation of sizes for each of the many types of bras sold by Figleaves. Daniel Nabarro, Managing Director of Figleaves commissioned Pankhurst Design and Development Ltd (PDD) of Hammersmith, London to design and build a bra-sizing rig. PDD in turn selected LiveWires to handle the PC-based software, data acquisition and motor control. Based around an adjustable artificial torso, the concept was that experienced bra fitters would be able to fit many bras in quick succession to the rig, with the precise size information being recorded automatically on a PC. To prevent this becoming extremely time-consuming and error-prone, as much of the process as possible would have to be automated.

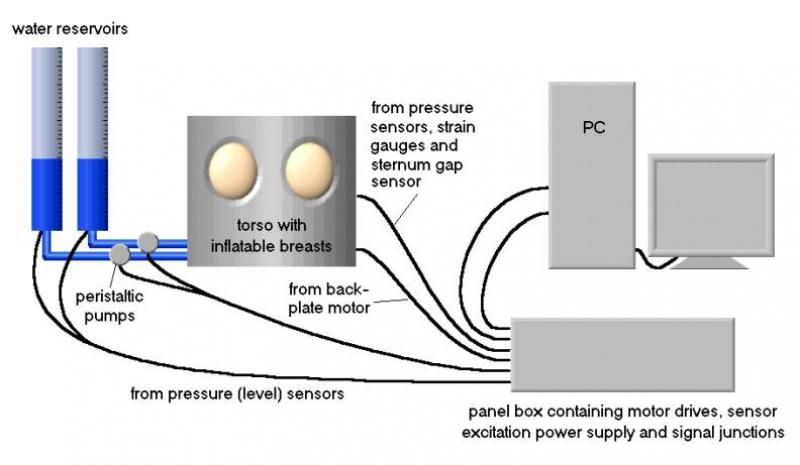

PDD developed a torso with 2 latex breasts that can be inflated and deflated by pumping water in and out of them. In this way, a good fit can be achieved for the “cup size” of each bra. The torso also has a motorised back plate that effectively allows the circumference to be altered, thus allowing the “band size” of each bra to be determined. A National Instruments PCI-7344 motor control card controls the 3 motors in the system – one for the back plate adjustment and two for the peristaltic pumps associated with each breast.

A significant challenge was to be able to determine the breast volume accurately and quickly after a good fit had been achieved. The irregular shape of the breast means that this cannot be achieved by simple distance measurements! Each breast is connected via a latex tube to a cylindrical reservoir of water. We decided to measure the volume in the reservoirs using pressure sensors in their base, and to use this to infer the breast volumes.

Breast size adjustment is achieved by the use of a joystick. The software reads the voltage produced from the joystick (0.5-4.5V) and uses it to set the speed of the pump motors, and alter it “on the fly”. In this way, the user has instant and complete control of the speed of pumping. Equal pump speeds inevitably do not quite result in equal volumes of water being delivered to the 2 breasts, so the software waits till the joystick is released and then makes a final fine adjustment to one of the pump motors to equalize the volume in the 2 breasts.

To calibrate the 2 breasts, a plastic cup of known volume is firmly placed in turn on them, and the joystick is used to inflate the breasts until a certain pressure (around 15PSI) is recorded by the pressure sensor in the breast. This indicates that the breast has completely filled the plastic cup. The user then tops up the water level in the cylindrical reservoir so that the water reading on the cylinder’s (inverted) scale equals the known volume of the plastic cup. Finally, the user presses a button in the software to enable the reading of the pressure sensor in the base of the cylinder to be taken. The software then adjusts the calibration factors that relate voltage from the pressure sensor in the cylinder to breast volume.

The software also continuously reads a second joystick and uses it to control the position of the torso’s back plate. Again, this is a variable-speed control.

The bra clips are attached to matching clips on the back plate which allow two strain gauges to measure the tension in the band of the bra. This information is stored by the PC in the results database.

A position sensor on the front of the torso detects whether there is a significant gap between the front of the bra and the “sternum” of the torso (i.e. the part between the two breasts).

The signals from the various sensors in the rig are acquired by the PC using a National Instruments PCI-6034E multifunction data acquisition card. Thus a very useful record of each fit is produced

To measure a single bra, the experienced fitter first scans its barcode, and the LabVIEWTM software looks up the details of the bra (manufacturer, type, nominal size etc) in an Access database. Then the fitter attaches the bra to the artificial torso and uses the two joysticks to achieve a good fit. Pressure and strain information can be used as an aid, or the fitter can merely go by the “feel” of the fit. The fitter then presses an on-screen “Store” button, which makes the program store to an Excel file the readings from the 7 sensors in the system, along with the cup volume and band size. During this process, alarms are generated in the software if any of the sensors show values outside certain limits.

A number of National Instruments products – motion control, data acquisition and powerful LabVIEW software – have been combined to perform efficient and accurate bra sizing. In time, this may revolutionize bra sizing in the UK and beyond!

Figleaves are planning to link the data collected from the rig to their website in the near future, and at the same time launch their specialized tape measures and measuring cups. The whole concept is known as T-bra.